How Tariffs are Transforming the U.S. Furniture Industry

Rising Tariff Costs and Market Uncertainty Challenge Furniture Importers

the American furniture sector is currently facing notable hurdles as import tariffs continue to rise, placing immense financial strain on manufacturers and retailers alike.Despite ongoing legal scrutiny of the so-called “reciprocal tariffs,” the 25% duties imposed specifically on imported furniture remain firmly enforced,complicating operational planning across the industry.

These tariffs were introduced under section 232 of the Trade Expansion Act and target a range of products including sofas, kitchen cabinets, and bathroom vanities. Although some tariff increases were postponed until 2027, persistent threats of additional trade restrictions have created an surroundings filled with unpredictability for businesses.

Peter Theran, CEO of a national home furnishings association representing retailers across the country, emphasizes that this instability severely disrupts long-term strategy progress. He notes, “The greatest obstacle right now is running a business amid constant uncertainty. Without clear guidance on future policies or costs, companies find it difficult to innovate or adjust.”

The Post-Pandemic Slowdown Amid Inflationary Headwinds

the pandemic years saw an unprecedented surge in demand for home furnishings as consumers invested heavily in upgrading their living spaces during extended periods at home. Historically low mortgage rates further stimulated housing purchases that naturally boosted furniture sales.

This boom led to strong growth throughout 2021; however, by late 2022 rising inflation combined with increasing interest rates triggered a market contraction-the first significant decline in over seven years according to recent industry reports.

By early 2025 when broader tariff hikes took effect, housing market activity had already decelerated sharply. Many smaller companies found themselves unable to absorb sudden cost increases directly linked to these trade policies without jeopardizing their financial stability.

A Surge in Bankruptcies Among Small Furniture Businesses

- Legacy Brands Falter: After nearly eighty years operating value City Furniture stores nationwide,American Signature Furniture filed for bankruptcy due to plummeting sales-down more than 25% between 2023 and 2025-and mounting losses worsened by tariff-related expenses.

- broad Industry Impact: At least ten other small-scale furniture firms have recently declared bankruptcy; many are liquidating assets or closing operations entirely because they lack resources compared with larger competitors better equipped to manage complex tariff environments.

- The Disproportionate Toll on Small Operators: Smaller businesses face greater challenges as they cannot exploit economies of scale or swiftly alter sourcing like multinational corporations can.

A vivid example comes from Joseph Cozza at East Coast Innovators-a supplier serving major retailers such as Macy’s-who was compelled to increase prices by up to 18% during peak holiday seasons solely due to higher import duties. This price adjustment significantly dampened consumer demand despite his efforts to maintain fair employee wages and keep his business viable.“It feels like I’m being penalized just for responsibly running my company,” Cozza shared while contemplating relocating from Philadelphia’s high-cost environment toward more affordable areas like North Carolina if conditions do not improve soon.

Larger Corporations Gain Ground Amid Shifting Market Dynamics

the imposition of tariffs has inadvertently benefited larger players within the U.S. furniture industry who possess greater financial strength and operational adaptability than smaller competitors struggling under similar pressures caused by import taxes over recent quarters.

- Ikea: In its fiscal year ending mid-2025 Ikea maintained relatively stable pricing alongside flat revenues compared with previous periods; increased expenses were mainly attributed to acquisitions rather than direct impacts from tariffs.

- RH (Restoration Hardware): Reported nearly a 10% rise in sales over nine months ending November while expanding profit margins despite elevated input costs partially linked with global supply chain disruptions influenced by tariffs affecting multiple regions including China and Southeast Asia markets such as Vietnam-which previously faced peak tariff rates exceeding 140% before partial relief measures were enacted earlier this decade.

- Williams-sonoma & Wayfair: Both companies posted modest revenue growth around four percent along with improved operating margins during comparable reporting periods even though they encountered higher import fees across various product categories sourced internationally impacted by these trade policies.

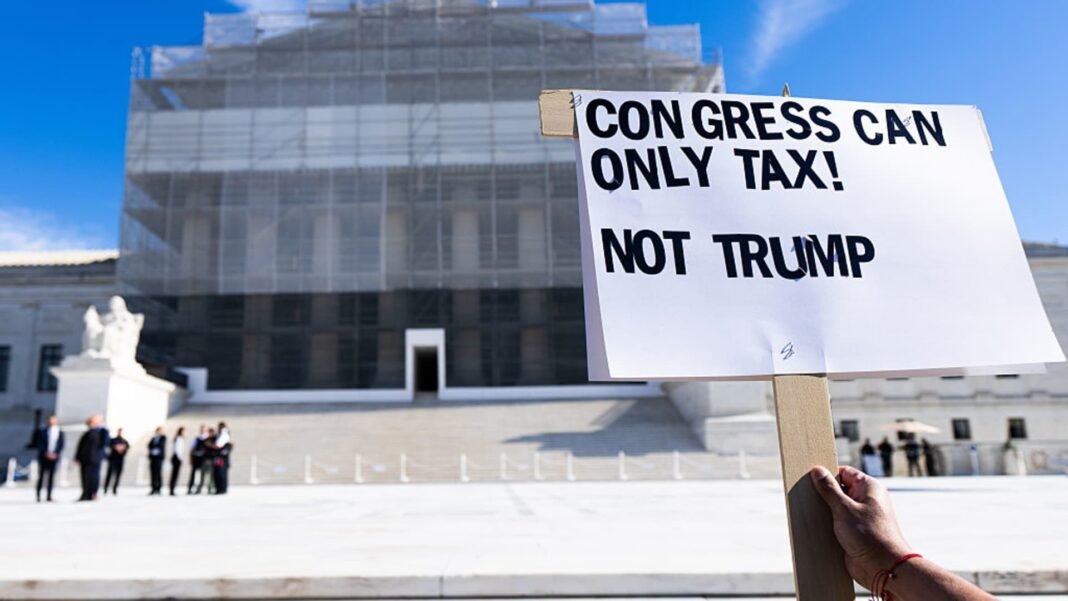

The Complex Legal Debate Surrounding tariff Authority

A pivotal legal issue currently before the Supreme Court questions whether former President Trump had constitutional authority under existing laws-specifically regarding reciprocal tariffs imposed through executive powers-to levy these taxes without Congressional consent.This decision could either nullify certain duties retroactively or uphold them perhaps leading toward steeper levies depending on judicial interpretation.*

“Even if confronted with worst-case scenarios regarding trade policy outcomes,” one top retail CEO remarked,

“we would quickly develop contingency plans-but right now no one can because everything keeps changing.”

Navigating Future Challenges: Strategies for Resilience in American Furniture Manufacturing

The combination of sustained tariff pressures alongside volatile economic factors such as fluctuating interest rates leaves many participants bracing for uncertain market conditions heading into mid-2026.

Smaller firms remain especially vulnerable without access to capital reserves or diversified supply chains necessary for rapid adaptation.

Meanwhile larger corporations continue leveraging scale advantages but must also prepare contingencies should legal rulings dramatically reshape current trade frameworks.

- Create agile sourcing strategies capable of swift response if new duties emerge following Supreme Court decisions;

- Pursue innovation emphasizing domestic manufacturing where feasible-to reduce dependence on imports subject to unpredictable taxation;

- Cultivate stronger partnerships between suppliers and retailers enabling shared risk management against sudden cost surges;

This evolving landscape demands vigilance from all stakeholders committed not only preserving but revitalizing America’s onc-thriving furniture manufacturing heritage amid global economic headwinds intensified by intricate trade policies impacting every level-from small family-owned shops barely surviving up through multinational giants competing fiercely both domestically and abroad alike.