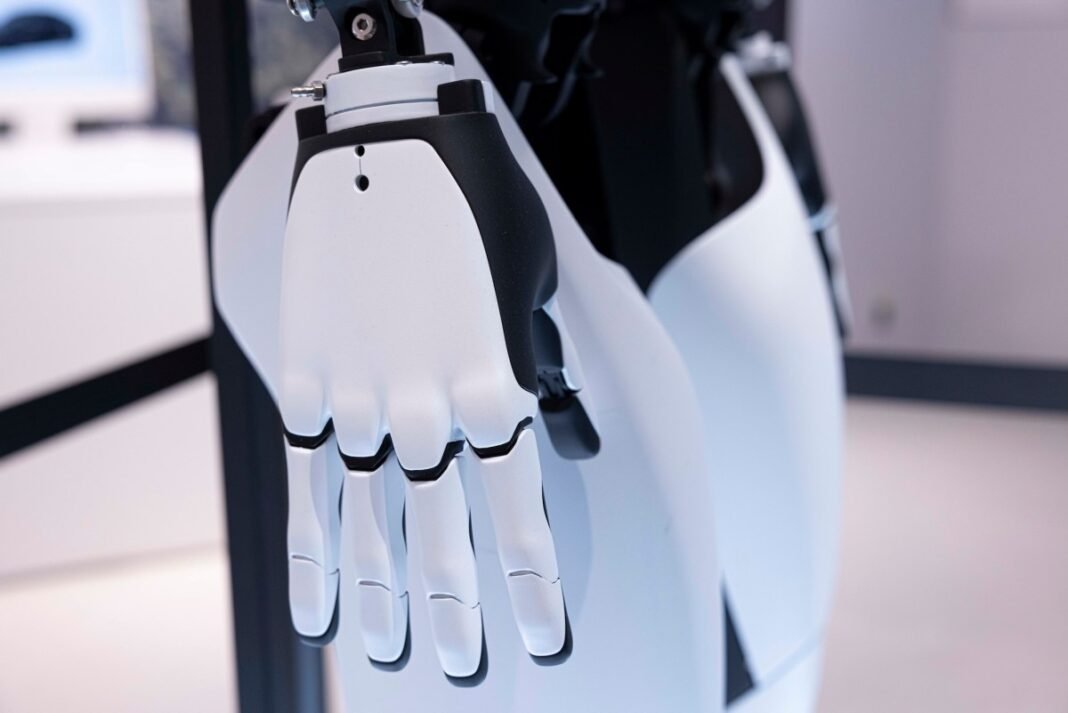

Leadership Change in Tesla’s Optimus Humanoid Robot Initiative

Milan Kovac Steps Down from Tesla’s Robotics Program

Milan Kovac, who has been at the forefront of tesla’s Optimus humanoid robot advancement, announced his departure from the company. In a heartfelt message shared on X, Kovac revealed that leaving was “the hardest choice” he has ever made. He emphasized that his decision was driven solely by personal reasons-specifically, a desire to reunite with family overseas after spending an extended period away from home. Despite stepping down, Kovac reaffirmed his unwavering support for both Elon Musk and Tesla.

context Behind the Transition

Kovac’s exit coincides with ambitious projections from tesla CEO Elon musk regarding the Optimus project. Musk recently stated that by year-end, thousands of these humanoid robots will be operational within Tesla factories. He further expressed confidence in scaling production rapidly to reach millions of units annually in the near future-a pace unprecedented in product manufacturing history.

Kovac’s Role and Contributions Over Nearly a Decade

Having dedicated close to ten years at Tesla, Milan Kovac initially contributed as a senior engineer on the Autopilot team before being appointed co-lead for optimus development in 2022. By late 2024, he had ascended to vice president overseeing all aspects of the program.

On his LinkedIn profile prior to leaving, Kovac described himself as leading not only the engineering teams behind Optimus but also those responsible for foundational software infrastructure shared between Autopilot and Optimus systems.

New Leadership Takes Charge

Ashok Elluswamy, currently serving as vice president of AI software at Tesla, is set to assume leadership over the Optimus initiative following Kovac’s departure. This transition aims to maintain momentum amid aggressive timelines and ambitious production goals.

The Broader Impact on Robotics and Automation trends

Tesla’s push into humanoid robotics reflects broader industry trends where automation is increasingly integrated into manufacturing processes worldwide. Such as, recent data shows global industrial robot installations surged by over 20% last year alone-highlighting growing reliance on robotic labour across sectors ranging from automotive assembly lines in Germany to electronics manufacturing hubs in South Korea.

“Scaling up humanoid robots like Optimus could revolutionize factory workflows much like how automated guided vehicles transformed logistics operations,” experts suggest.

Looking Ahead: The Future of Humanoid Robots at scale

If triumphant at scale-as envisioned by Musk-the deployment of millions of units annually would mark one of history’s fastest product rollouts while potentially reshaping labor dynamics within factories globally. Such advancements may parallel transformative moments seen during previous industrial revolutions but accelerated through cutting-edge AI integration combined with robotics hardware innovation.